CNC routing uses a Computer Numerical Controlled machine to cut, carve, slice or mill a range of materials to create a finished product. Specialised tools are used and programmed to complete the required routing. The action of the tooling is driven by custom software programmes created by the CNC operator.

CNC routing replaces a number of earlier processes such as routing, milling and machining. By using computer-based programming the level of finish, complexity, accuracy and the speed of routing has increased. This has made the process a cost-effective process for manufacturing a wider range of products, especially plastic prototypes.

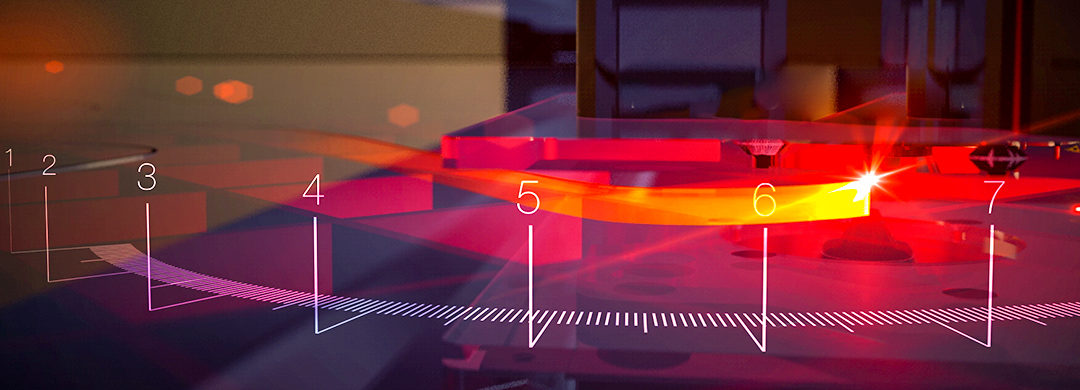

With 5axis CNC the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the material from any direction. In other words, you can process five sides of a part in a single setup.

A CNC router can be used on a variety of materials including wood, composites, aluminium, steel, plastics, glass, and foams.

More about CNC Routing

CNC routing can be used to manufacture a range of products such door carvings, decorations, sign boards, wooden frames, mouldings, furniture, musical instruments and wood panels. It is increasingly used in sign making.

It is also often a finishing process for other manufacturing or fabrication services. For example product made using vacuum formed are often trimmed and finished using the CNC router.

With today’s increasing technology a universal routing tool is sufficient to deliver high quality routing across a range of substrates at high speed.

With all this sophisticated kit and tooling, commercial routing is a complex process that requires skilled technicians to deliver projects at maximum efficiency and highest finishing standard. When choosing a partner for your project get to know not just the available tech but their level of experience with the material and product.

Recent Comments