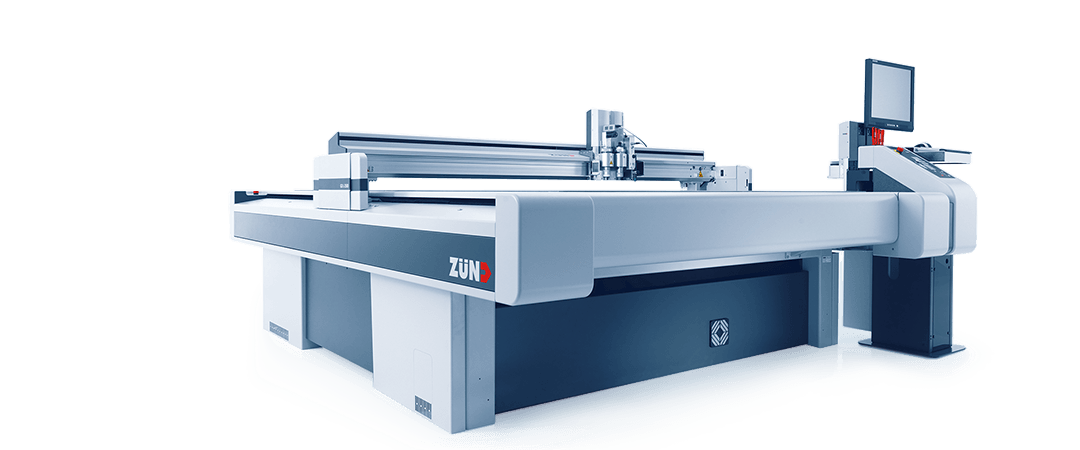

Our CNC routing capability has been expanded by the addition of one of the next generation cutting systems. The Zund G3 series offers the ultimate in high speed high quality machining.

The leading edge features and the benefits they bring to CNC routing projects include

- Modular Tooling. It has never been easier to configure the exact tooling for even the most complex projects.

- Tool Management. Modular tooling not only offers precise configuration it also makes setting up and changing tooling quick and easy. We can act fast to any on production tooling requirements required – keeping your job on schedule and on budget

- High Precision. Zund have designed the G3 so that all elements – from drive systems to cutting blade – work in perfect harmony to enable an efficient and ultra precise CNC routing service. Efficiency helps us lower costs, reduce lead times and,, of course, minimise the impact on the environment of your project

- Powerful, Robust Performance. With machines designed to operate 24/7 and with minimal downtime we can offer an around-the-clock service, so we can tackle large volume projects and ‘last minute’ requests.

- Semi-automated Production. Loading and unloading occurs concurrently with production. While the operator loads or unloads, the cutting continues. Again this will help reduce production times – and that will help reduce costs.

The introduction of the Zund G3 to our suite of CNC and cutting machines we not only have a larger capacity we also have next generation levels of quality, efficiency and sustainability.

To discuss how Zund G3 I the hands of our skilled team can power your next CNC routing job call us on 0121 580 3080

Recent Comments