It is reported that in the UK, an estimated 1 in 4 workplace injuries and eight out of ten workplace fatalities involve mechanical equipment so reducing the hazard of operating equipment is essential and machine guards have an important job to do.

Machine guarding is mostly used where a hazard cannot be eliminated or substituted with a safer alternative. The most common machine guard type is a fixed guard which forms a barrier between the machine and the operator and prevents contact with the machine.

There are legal procedures and regulations in force to minimise risks of machinery usage in the workplace and to protect those working with machinery. Employees who use machinery are exposed to risks during operation, adjustment, maintenance and lubrication of machinery and all risks need to be eliminated as far as are possible. To prevent injuries and fatalities, securely fitted and installed machine guarding is used to guard against dangerous and moving parts of machinery.

Risk assessments will identify areas for potential risk and how these can be minimised, and the guarding will be taken into consideration during this assessment. This is not a one-off procedure; procedures need to be in place to ensure regular checks are carried out.

To help identify machine parts that pose a danger, areas and points should be observed and investigated. Common factory and workshop machinery that often require guards include:

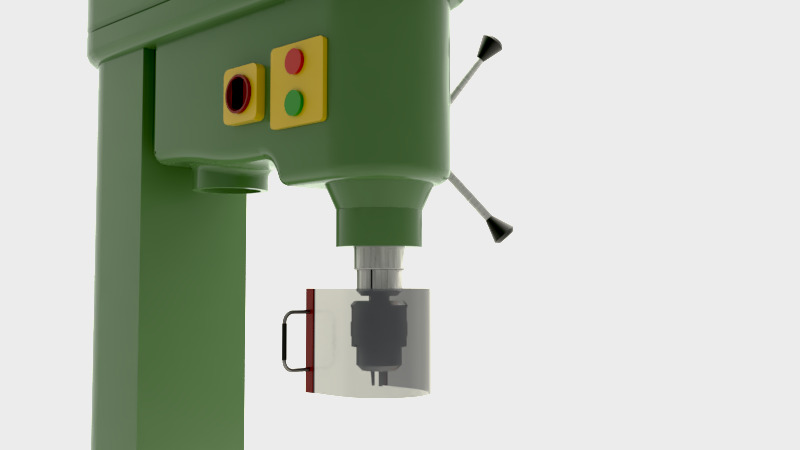

- Drilling machines

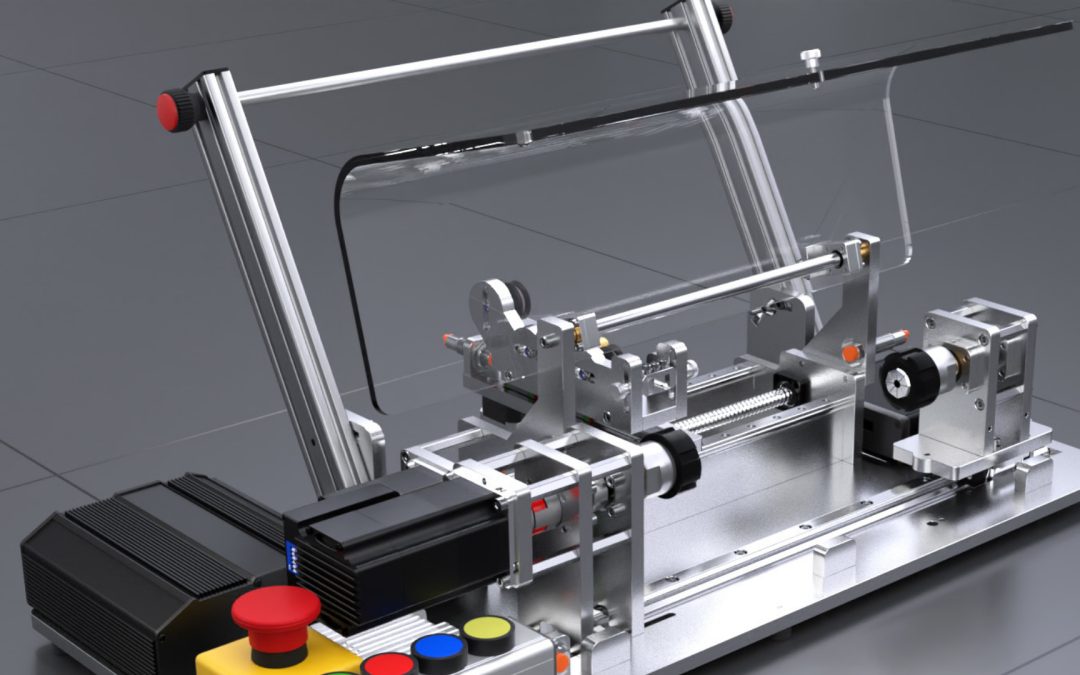

- Milling machine such as CNC routers and millers

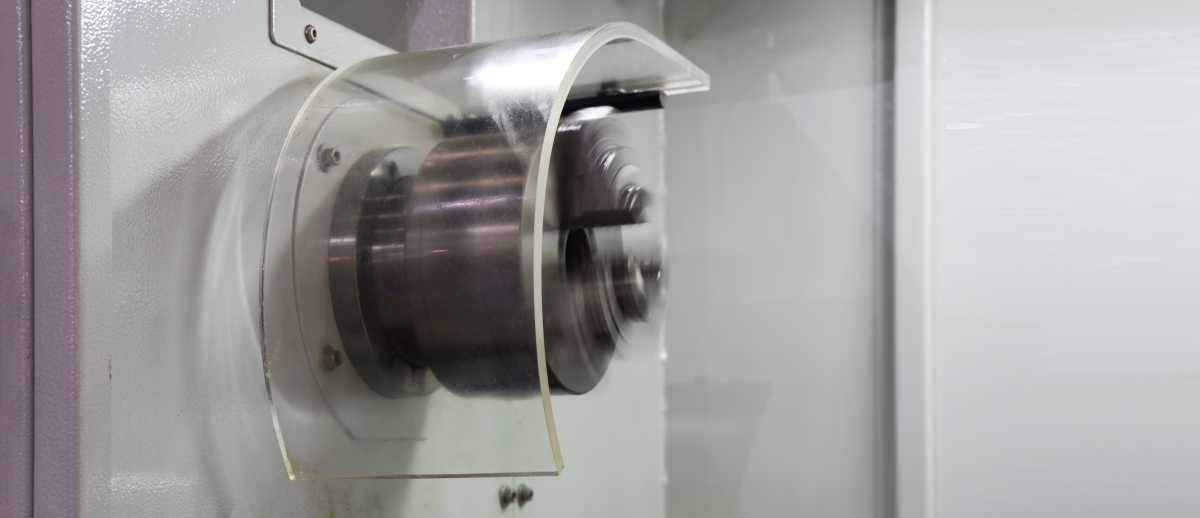

- Lathes

- Portable power equipment and tools such as chippers

- Hydraulic Presses

- Surface and pedestal grinders

Machine guarding is mostly used where a hazard cannot be eliminated or substituted with a safer alternative. There are many machine guard types that can be used according to the type of control requirement. One machine guard type is a fixed guard which forms a barrier between the machine and the operator and prevents contact with the machine.

It is important that any machine guards are of the highest standard and compliant with any H&S rules. Replacement guards need to be of the at least the quality of the guard they are replacing. Whether ordering off-the-shelf or bespoke guards, always choose a quality supplier and ask them to confirm the quality of the material used and processes undertaken. Check to see if they have any recognised Quality Certification, and experience within the sector.