Machine Guards

High quality machine guards and covers for fixed and portable machinery

MASSIVE PLANT LIST

IS0 9001

UNBEATABLE QUALITY

MATERIAL CREDIBILITY

H&S COMPLIANT

Wrights Plastics is a leading manufacturer of high-quality, standards-compliant polycarbonate-based safety guards for machines.

We manufacture high quality machine guards for all types of manufacturing & finishing machines including CNC machine guards, cutting & milling machines, lathes and grinding machines.

We manufacture to clients’ specific designs or requirements, all designed & made to relevant occupational safety standards including relevant PUWER regulations. Our inhouse team can help develop ideas or rough drawings into useable designs & effective CAD.

Why choose Wrights Plastics?

- Over 50 years’ experience of manufacturing high quality products for a range of service, industrial and automotive customers.

- Our material expertise ensures we manufacture polycarbonate safety guards for machines to the highest quality for safety and durability.

- Inhouse design & CAD service, aiming to develop the most effective solution first time, every time

- Ongoing investment in sector leading equipment means faster turnaround, lower costs and the most sustainable solutions.

- Your account manager will keep you updated from initial costings to final despatch.

We manufacture PETG and cast acrylic and polycarbonate machine guards depending upon requirements – our expert team will advise on the most suitable material for the project.

Quick Quote Form

POWER TOOL & EQUIPMENT GUARDS

CONVEYOR BELT POWER UNIT GUARDING

CNC GUARDS

LATHE GUARDS

ANTI-SPLASH SCREENS

Machine Guards Solutions

Our polycarbonate safety guards solutions offer cost-effective products for the most common manufacturing & finishing machinery such as CNC machining and laser cutting & profiling machines.

- Drilling machine guards protect users from both the dangerous rotating parts of a drilling machine and flying swarf. We make a comprehensive range of guards to suit virtually all types and sizes of bench and pedestal drilling machines

- Milling machine guards. We can make CNC guards to suit all leading CNC routers and non-CNC milling and routing machines.

- Lathe Guards protect operators from coming into contact with the dangerous rotating parts of a lathe and our range of lathe chuck. guards offer PUWER compliant guards at cost-effective prices.

- Covers and guards for portable power equipment and tools.

- Hydraulic Press Guards

- Surface Grinder Guards. Pedestal Grinder Guards

- Anti-Splash Screens

- Conveyor belt transmission equipment Guards

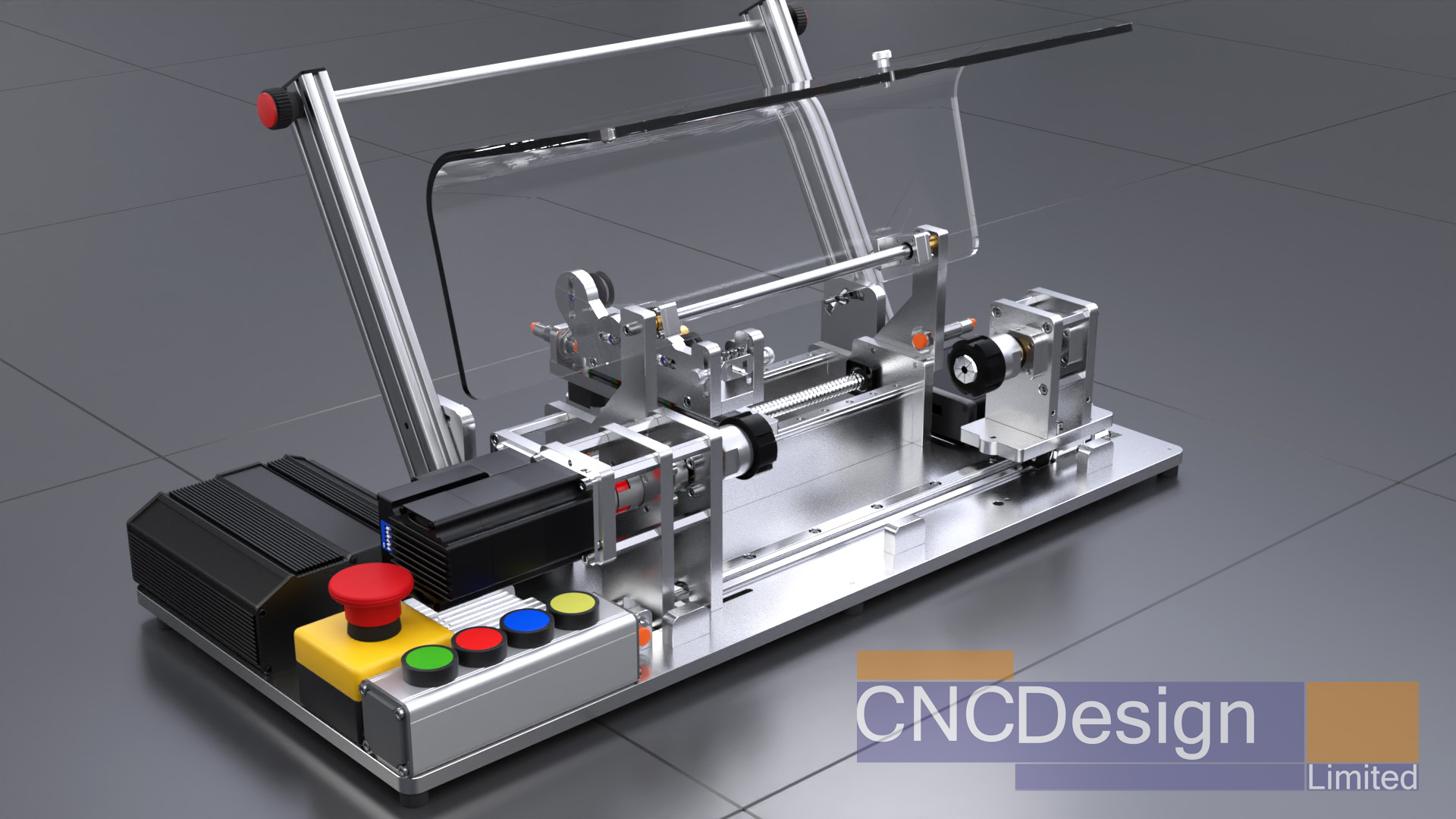

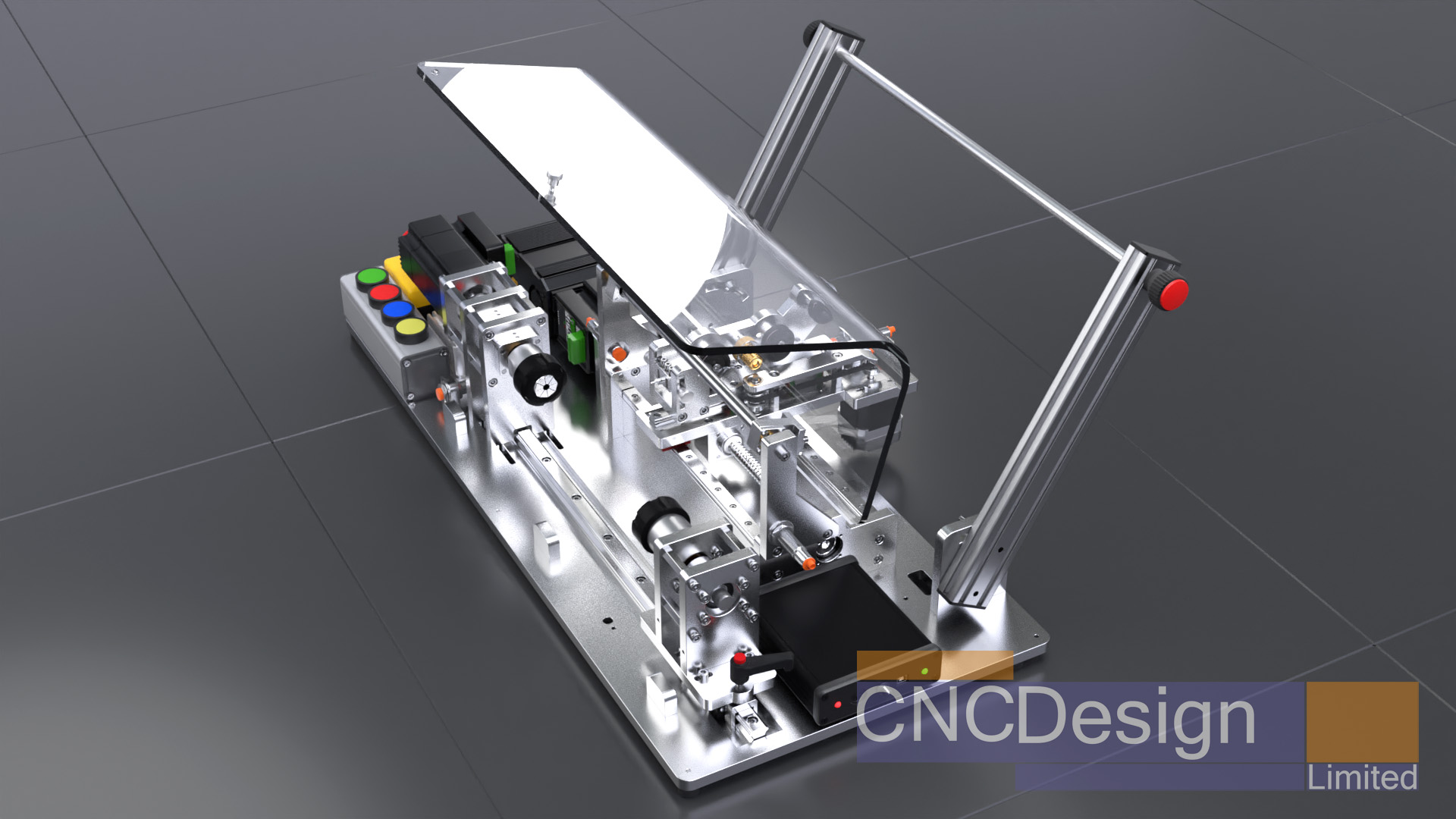

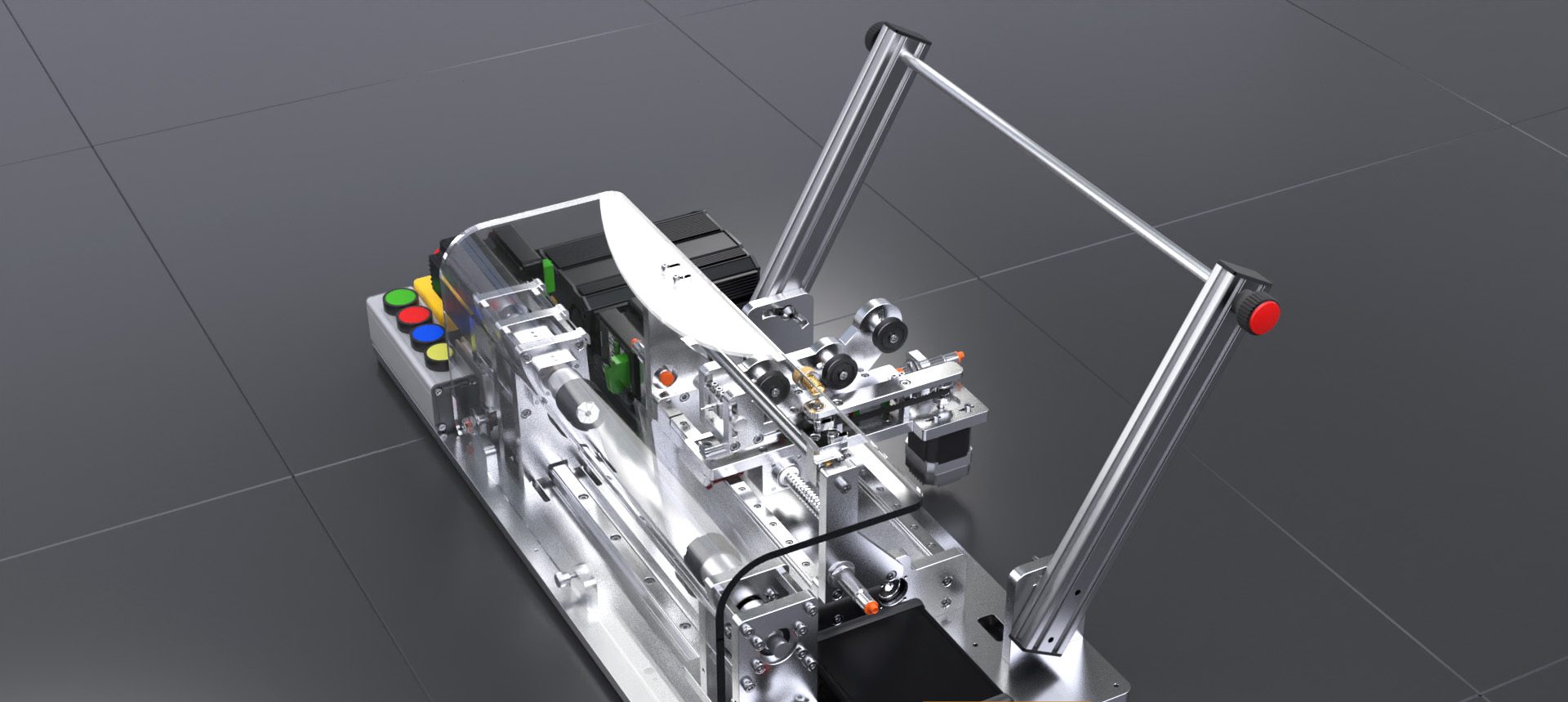

Our latest polycarbonate machine guard project saw us manufacture 25 clear polycarbonate CNC guards for CNC Design Ltd to the client’s specification.

We manufacture high-quality durable covers for Timberwolf, a global manufacturer of wood chippers for over 35 years supplying a range of industries, including arboriculture, groundcare, horticulture, local authorities and estates.

Importance of Safety Guarding

Safety guarding refers to the measures and devices put in place to protect workers from hazardous machinery and equipment. This can include physical barriers, protective shields, and automated systems designed to prevent injuries and accidents.

Safety guarding is essential for several reasons. Firstly, it significantly reduces the risk of workplace injuries. Machinery and equipment can pose serious hazards, including crushing, cutting, and entanglement. By implementing appropriate safety guarding, these risks can be minimized, ensuring that employees can perform their tasks without fear of harm.

Furthermore, safety guarding helps to comply with legal and regulatory requirements

- Hazard Prevention: Guards are primarily employed to prevent contact between workers and moving parts, such as blades, belts, or gears. By effectively enclosing these hazardous areas, guards eliminate the possibility of accidental contact, thereby reducing the risk of severe injuries or even amputations.

- Material Containment: In certain machines, guards serve the purpose of containing materials, chips, or sparks that may be ejected during operation. This containment feature prevents debris from causing harm to workers or damaging other equipment in the vicinity.

- Noise and Dust Reduction: Some guards incorporate additional features, such as soundproofing or dust extraction capabilities. These guards contribute to a safer working environment by reducing noise levels and minimizing the exposure to harmful airborne particles.

Importance of Machine Guards:

- Injury Prevention: The foremost importance of machine guards lies in their ability to prevent injuries. By acting as a physical barrier, they significantly reduce the risk of accidents, safeguarding workers from potential harm and protecting their overall well-being.

- Compliance with Regulations: Employing guards is often a legal requirement in many jurisdictions. Complying with safety regulations not only avoids legal penalties but also demonstrates a commitment to worker safety and fosters a positive work environment.

- Enhanced Productivity: Guards, when properly designed and implemented, can improve productivity. By minimizing the occurrence of accidents and injuries, workers feel more secure, leading to increased focus, confidence, and efficiency in their tasks.

Guards are indispensable safety measures for both static and portable machinery. Their uses, ranging from hazard prevention to noise reduction, make them essential components in industrial settings. By understanding the importance of machine guards, companies can prioritise worker safety, prevent injuries, ensure regulatory compliance, and create a productive work environment that values the well-being of its employees.

Manufacturing milling machine guards are a crucial aspect of workplace safety in industrial settings. These protective measures aim to prevent accidents and injuries by enclosing the machinery and implementing safety devices like interlocks. Adhering to OSHA-compliant standards and employing advanced guarding technology ensures operator protection during milling operations, reducing the risk of workplace hazards and enhancing overall productivity. Proper guarding assessments, custom enclosures, and safety-conscious protocols contribute to a safe and efficient manufacturing environment.