Plastic Products Manufacturer

We’ve been making high quality plastic products, parts and components since 1969.

MASSIVE PLANT LIST

IS0 9001

OVER 50YRS' EXPERTISE

MATERIAL CREDIBILITY

INHOUSE FINISHING & FABRICATION

Welcome to Wrights Plastics Your Trusted Plastic Products Manufacturer

Are you in search of a reliable and innovative plastic product manufacturer? Look no further! As a leading UK plastic fabrication company, we take pride in our decades of expertise and dedication to delivering top-notch plastic products, parts and components for a huge range of clients across many sectors. Whether you require custom-designed products or mass-produced plastic parts, our cutting-edge processes and skilled teams ensure unparalleled quality and efficiency.

Our Expertise:

- Quality Assurance: At Wrights Plastics, quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process to ensure that every product leaving our facility meets the highest standards.

- Innovative Designs: Our skilled team of designers and engineers thrive on creativity and innovation. From initial concept to final production, we work closely with you to develop functional and aesthetically pleasing plastic solutions.

- Material Expertise: With our extensive knowledge of various plastic materials, we guide you in selecting the right material for your application. Whether it’s ABS, acrylic, polycarbonate, or any other specialty plastic, we optimize the choice to meet your specific needs.

- Environmentally Conscious: Sustainability is a core value at Wrights Plastics. We strive to minimize waste, implement eco-friendly practices, and use recyclable materials wherever possible. Partner with us for responsible and environmentally conscious plastic manufacturing.

Quick Quote For Your Next Project

MACHINE GUARDS

POINT OF SALE DISPLAY

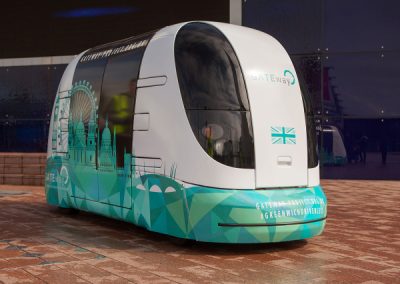

STREET FURNITURE

COVERS, BACKBOARDS & HOODS

AUTOMOTIVE PARTS & COMPONENTS

Complete service from a leading plastic products manufacturer

Our Process:

Consultation: We begin every project with an in-depth consultation to understand your requirements, design preferences, and desired outcomes.

Design and Prototyping: Our team can create detailed designs and provide plastic prototypes to help you visualise, test and finesse the final product and make necessary adjustments.

Manufacturing: Once the design is approved, we initiate the production process, using the most suitable plastic fabrication method for your project.

Quality Check: At every stage, our quality control team rigorously inspects the products to ensure they meet the highest standards of durability and precision.

Delivery: With efficient logistics and on-time delivery, we make sure your plastic products reach you when and where you need them

Why Choose Wrights Plastics?

- Experience and Expertise: With over 50 years of industry experience, Wrights Plastics has the knowledge and skill to handle projects of any scale and complexity.

- Custom Solutions: Our dedication to providing tailored solutions sets us apart. No matter the project, we always go the extra mile to deliver products that perfectly match your requirements.

- Advanced Technology: We invest in cutting-edge machinery and technology to optimize the manufacturing process and deliver superior plastic products.

- Customer-Centric Approach: We prioritize clear communication, on-time delivery, and exceptional customer service. Your satisfaction is our ultimate goal.

WE MANUFACTURE THESE PLASTIC PARTS, PRODUCTS & COMPONENTS

POINT OF SALE / POINT OF PURCHASE

AUTOMOTIVE COMPONENTS

SIGNAGE

BACK BOARDS

COVERS

HOODS

TRAYS

MACHINE GUARDS

SAFETY PANELS

SCREENS

STREET FURNITURE

HUGE PLANT LIST

ISO 9001 ACCREDITED

Our ISO 9001 accreditation is recognition of our commitment to quality and excellence. With almost fifty years’ experience in thermoforming and an extensive range of manufacturing, industrial and retail clients, we combine the latest technology with old-school service to provide a ‘less stress’ service from end-to-end.

OUR PLASTIC PRODUCT MANUFACTURING PROCESSES

Read about our recently completed projects