Plastic Prototyping

Bringing your bright ideas to market with our range of rapid prototyping processes

Our plastic prototyping services use the latest technology to deliver high quality cost-effective acrylic / plastic prototypes. Our plastoc prototypes can withstand rigorous testing – giving you confidence in the final design before investing in tooling and manufacturing.

Our plastoc prototyping service combines design and manufacturing expertise with advanced manufacturing technologies such as 3D printing and more traditional manufacturing techniques like CNC machining and thermoforming processes to provide you with the perfect solution for your plastic prototypes and low volume needs.

What Is Plastic Prototyping?

Plastic prototyping involves using specialised techniques for making high-quality physical models of a design idea. Prototypes are useful for design improvement, as stepping stones to full production or for engineering testing. They are meant to be made quickly and economically, without the need for the investment in hard tooling.

Advantages of Rapid Plastic Prototyping

- Show your customers and investors a physical model of your product concept

- Demonstrate the appearance, dimensions and features a product

- Market test before going into production

- Identify and eliminate design flaws

- Determine the best manufacturing and finishing processes

- Create multiple versions with different materials, colours, finishes , sizes etc

Why choose our services?

We believe successful plastic prototyping is based on three elements:

- With over 50 yrs. experience we can advise on design, manufacturing and market place before any prototyping starts. Our specialist CAD team can turn your concept into a usable 3D design.

- With a heritage of fabrication skills we can ensure the prototyping fits your exact requirements,

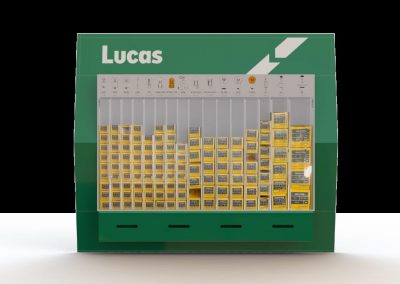

- We offer both the latest in 3D printing technology as well as traditional manufacturing processes such as CNC routing and thermoforming to develop and manufacture the perfect prototype. Our 5 Axis CNC routing offers virtually 3D manufacturing. With a huge Wrights Plastics Plant List May 2018 we have the essential equipment to provide rapid, cost-effective prototypes across a range of substrates.

Rapid Plastic Prototyping Quick Quote

Low Volume Plastic Manufacturing

When compared with injection moulding, vacuum forming and thermoforming is a more financially viable alternative for larger, lower volume parts. In addition to significantly reduced prototyping and production tooling costs, thermoforming provides a much faster product development time.

Our 50 years expertise in thermoforming processes will ensure we can manufacture even low volume parts cost-effectively. Our investment in cutting-edge technology guarantees we can rapidly manufacture high quality products with minimum wastage and energy use.

Our design team will advise on the most effective solutions and we can also offer a complete ‘design to delivery’ service which handles everything including warehousing and distribution if required.

Benefits of Plastic Prototyping

Advanced materials can closely match the look, feel, and material characteristics of parts produced with traditional manufacturing processes such as injection moulding. Materials can simulate parts with fine details and textures, smooth and low-friction surfaces, rigid and robust housings, or soft-touch and clear components. Manufactured parts can then be finished with secondary processes like machining, polishing and printing to replicate any visual attribute of a final part, as well as machined to create assemblies from multiple parts and materials.

Plastic components for industrial and automotive sectors require extensive functional testing to see how a part or assembly will function when subjected to stresses and conditions of in-field use. High-performance prototypes can withstand thermal, chemical, and mechanical stress. The technology also provides an efficient solution for creating custom test fixtures to simplify functional testing and certification by gathering consistent data.

To find out more or discuss your needs call us today on 0121 580 3080