We are pleased that a recent plastic fabrication project received public praise from the customer.

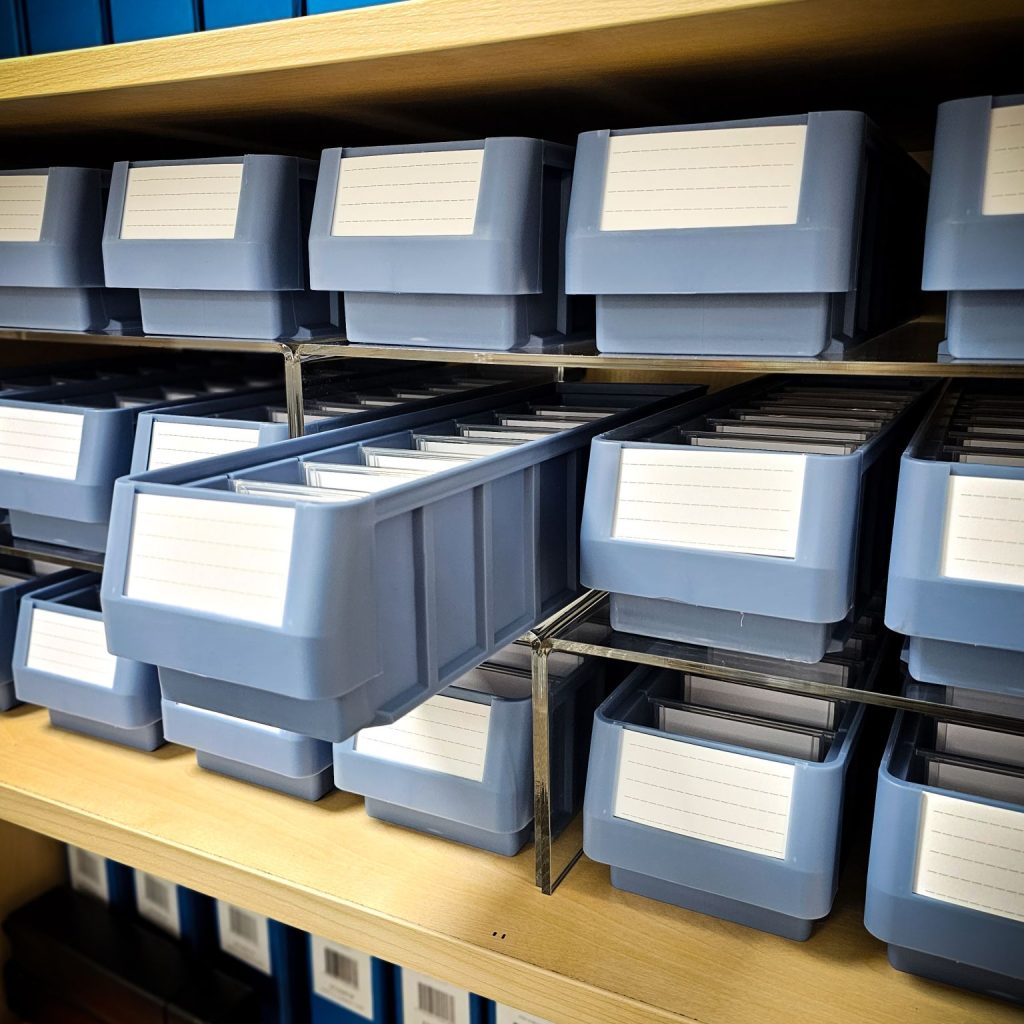

Lewis Cavanagh of Prima Dental Group needed a solution to storing Product Development samples that was efficient in both spacial consumption and accessibility. Space was tight and there was no off-the-shelf solution available. After a brief internet search Lewis fired off an email to our sales team, and we were able to manufacture the platforms to his exact requirements.

The platforms were manufactured from clear 5mm acrylic – strong enough to hold the weight of the sample boxes and durable enough to make sure these platforms will last & last. They were manufactured using a couple of our core skills: the laser cut plastic was passed to the line bending team for completion. The project was completed within a couple of weeks.

Lewis took to LinkedIn in give positive feedback on the project.

From concept to reality. It’s the single best element of Engineering. We needed a solution to storing Product Development samples that was efficient in both spacial consumption and accessibility. Working with Wrights Plastics, the following solution was executed perfectly – this is exactly what I envisaged. Will I use them again? ABSOLUTELY! 🤝

We thank Lewis for the opportunity & hope we get to work together again.